TRANSMISSION

Absolutely reliable products with a wide range of choices for the most diverse applications. These characteristics distinguish the components

included in this powerful family.

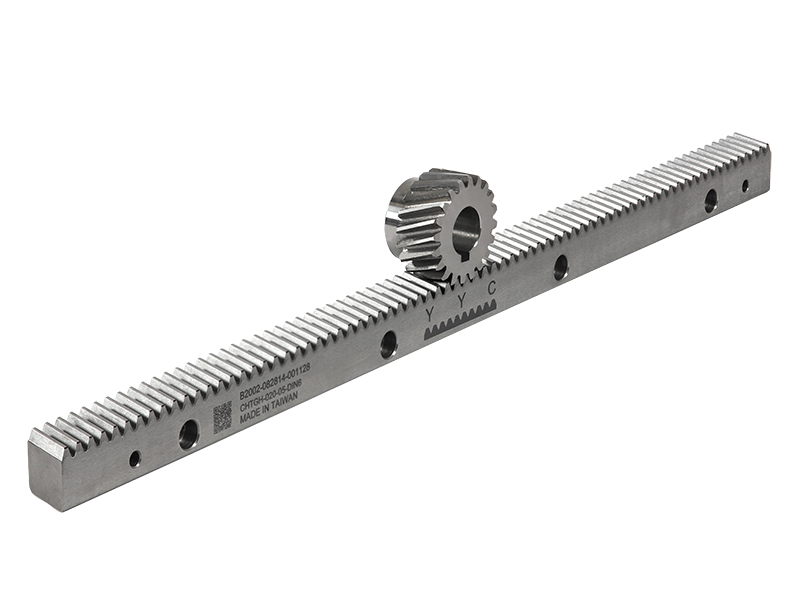

Racks And Pinions

RACKS AND PINIONS

Romani Components boasts a very strong and exclusive partnership with YYC, a Taiwanese manufacturer of precision racks and pinions that has been present on international markets for several years, due to the continuous development of the quality of its products, technologies and infrastructure. One of the most important innovations was to replace the classic induction hardening with a more effective diode LASER TEMPING. In addition to guaranteeing the same hardness, LASER TEMPRA avoids excessive deformation of the workpiece that would entail an onerous and delicate straightening process, especially in smaller modules. Here, laser systems have a clear advantage: the laser beam together with the precisely focussed shaping optics of the beam enables selective heat treatment, where only selected areas of the components are processed, unlike through-hardening.

The production range of racks and pinions includes metric pitches from module 0.5 up to module 30, straight or helical toothing, from Q10 up to Q5 quality and lengths up to 2000mm, all manufactured to customer specifications. For the harshest environments, racks and pinions are available in stainless steel and coatings such as black oxide and chrome.

Standard racks from module 1.5 to module 4 in C45 steel are always available from our stock in 500/1000/2000mm lengths in Q6 quality, with straight and helical right-hand 19°31′ 42″ toothing, hardened on the teeth and fully ground with side drilling that allows for immediate series assembly for unlimited strokes, ideal for OEMs requiring just-in-time delivery schedules.

Precision gears up to module 30, with finished tool or ground profiles, straight or helical teeth, right- or left-tooth in C45, 18NiCrMo5, 20MnCr5 steel, fully customisable.

Our engineers are also able to determine the relevant data, such as module and rack section based on the application data concerning: speed, mass to be moved, cycle and required positioning accuracy.

Special executions;

- Racks with integrated cusp guide

- Racks with integrated recirculating ball guide for combined execution. Hardened guideways and racks with ground toothing and raceways.

- Racks with integrated gantry guidance for 7th axis

Solutions that bring significant advantages in terms of reduced assembly time, greater precision, and simplified execution of the surrounding construction.