HYDROSTATIC SYSTEMS

High competence and high technology are the hallmarks of HYPROSTATIK products. Linear axis slides, screws, spindles, rotary tables, bearings, tailstocks and more.

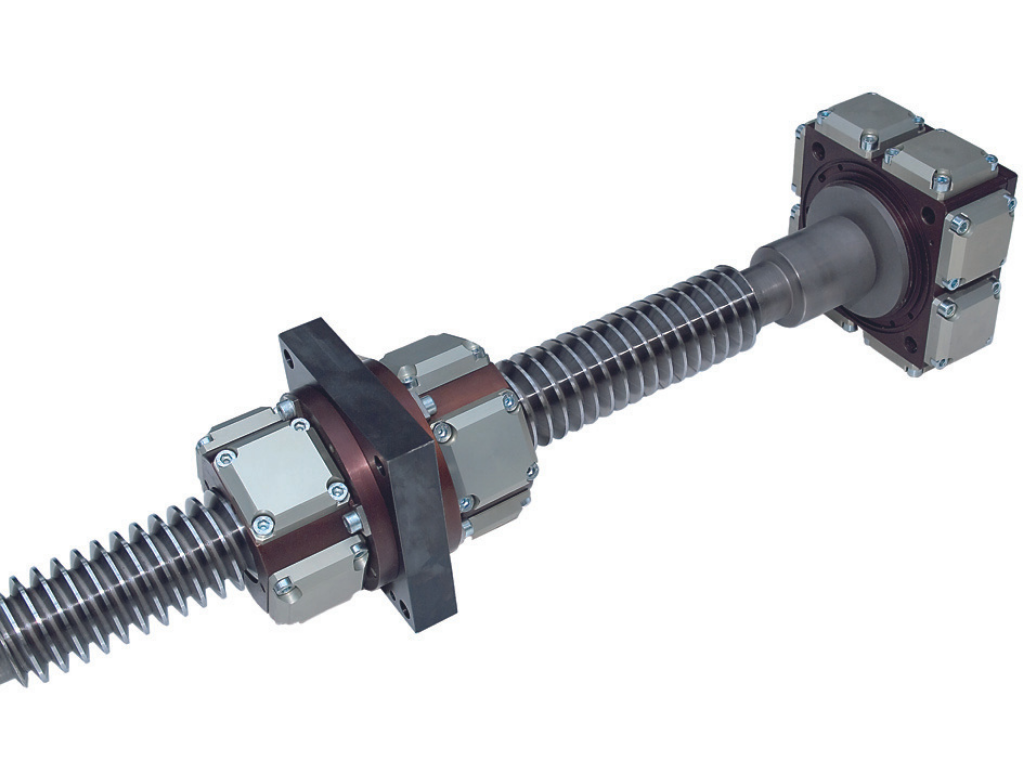

Hydrostatic Screw

HYDROSTATIC SCREW

Advantages over the ball screw and rolling bearing at a glance:

– Wear-free, as there is no contact during operation

– No loss of accuracy, even in long operation under full load at maximum

– Speed

– Frictionless at low speeds

– No reversal of the frictional force when changing the direction of rotation

– Transmits the slightest rotary movements

– No stick-slip effect even at low speeds

– No fluctuations of the frictional torque due to the ball circulation

– Higher axial stiffness like ball screws

– Much better damping, thus better workpiece surface and tool life

– No vibrations due to the ball circulation

– Also suitable for high speeds and accelerations

– Low-cost alternative to the linear motor with higher accuracy, much lower

– Heating

– Much lower power loss and therefore no problems with chips on the permanent magnets

– Many times lower cooling capacity than linear motors

Technical features at a glance:

– Absorption of axial and radial forces as well as moments suitable for single-sided bearing of the threaded spindle-

– High-precision bearing of the screw drive

– Double cones suspended between hydrostatic pockets for bearing in “O” arrangement

– Integrated flow control by pocket pressure only, only one hydraulic connection,

– No additional electronic control required

– All supply lines and drains in the flange area

– Optional sealing to one side by sealing air/gap seal or sliding seal

– Spindle ends are made according to customer requirements

The hydrostatic nut is adapted to:

– Axial load in both directions

– max. Speed

– Desired stiffness

Advantages of hydrostatic bearings over rolling bearings at a glance:

– Wear-free, as there is no contact during operation

– No loss of accuracy, even in long operation under full load at maximum speed

– Frictionless at low speeds

– No reversal of the frictional force when changing the direction of rotation

– Transmits the slightest rotary movements

– No slip-stick effect even at low speeds

– No fluctuations of the frictional torque due to the ball circulation

– Much better damping, thus better workpiece surface and tool life

Technical features of the hydrostatic bearings for supporting the threaded spindle:

– Absorption of axial and radial forces as well as moments suitable for single-sided bearing of the threaded spindle

– High-precision bearing of the screw drive

– Double cones suspended between hydrostatic pockets for bearing in “O” arrangement

– Integrated flow control by pocket pressure only, only one hydraulic connection, no additional electronic control required

– All supply lines and drains in the flange area

– Optional sealing to one side by sealing air/gap seal or sliding seal